Welcome to visit our factory !

Welcome to visit our factory !

Email:

hnty@ayxingsheng.comCaSi Wire | CaFe Wire | Carbon Wire | FeTi Wire | ReSiMg Wire | Pure Ca Wire | FeS Wire

Ca30 Si60 | Ca30 Si58 | CaSi Powder - Ca28-30% Si50-60% | Third Party Inspection

Provide FeSi 72% | FeSi 75% | FeSi 70% | FeSi Powder | Factory & Manufacturer

Silicon Metal 553 / 441 / 421 / 3303 / 2202 / 1101, Customized According to Your Needs

HC silicon 6818/6515, various grade for choice, Materials for Steelmaking

SiMn-6517 /6014, silicon manganese is used as a deoxidizer and an alloying element in stee.

Ferro manganese is an ferro alloy whose main components are ferro and manganese. It is used as a deoxidizer, desulfurizer and alloying agent in iron and steel work.

Silicon Slag is a by-product of silicon metal production. It's the separated part which are less purity of silicon metal.

Micro Carbon | Low Carbon | Medium Carbon | High Carbon | Various Grade for Choice. Ferro Chrome is an ferro alloy of chromium and iron, containing 50% to 70% chromium.

Silicon carbide contains two common basic varieties: black silicon carbide and green silicon carbide

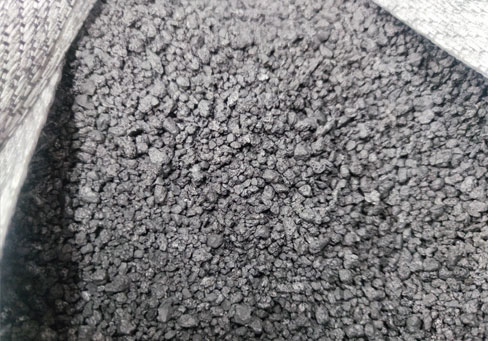

● FC: 99%, S: 0.05% | FC: 98-99%, S: 0.2% | Size: 0-2mm 3-8mm 4-20mm or customized

● High Carbon Level | Low Sulfur | Quality Assured | Support Third-party Inspection | SGS

Recarburizer, also know as carbon additive, carbon raiser. It is a product for increasing the carbon element (C).

Recarburizer is quality material as reductive agent and carbon addictive in steelmaking, with the characteristics of high recovery rate, low sulfur and phosphorus content, no pollution. It is divided into ordinary carburizer and graphite carburizer. According to different smelting processes, carbon can be added during steel making and casting to increase the strength of steel and casting.

Recarburizer used in casting, can greatly increase the dosage of scrap steel, reduce the dosage of pig iron or no iron. Electric furnace smelting way of feeding, recarburizer with scrap steel should be burden to put together, such as small doses of adding can choose to add in the hot metal surface. But want to avoid mass feeding into the molten iron, in order to prevent excessive oxidation by carbonization effect is not obvious and the carbon content of the casting is not enough. Increased carbon agent, the dosage according to the ratio of other raw materials and carbon content. Different kinds of cast iron, according to need to choose different types of recarburizer. Choose recarburizer characteristics itself pure carbon graphite material, reduce too much impurity in the iron, carburant choose appropriate which can reduce the cost of castings.

1. High Carbon Levels

Our carbon levels can reach in the excess of 99% providing maximum cost efficiency. High carbon recovery ensures lower material consumption and processing time.

2. Low Sulfur

Our Carbon Additives is naturally low in Sulfur reducing costly post melting sulfur treatments.

3. Low Ash & Moisture Levels

Less slag formation due to our inherent low ash and moisture content resulting in better cast quality and productivity.

4. High Thermal & Electrical Conductivity

High Thermal & Electrical Conductivity ensure high dissolution rate resulting in higher production efficiencies and lower operating cost.

5. Quality Assured

Manufactured to our highest quality control to guarantee consistent cast quality and cost.

| Grade | FC | S | Ash | VAD | H2O |

| ≥% | ≤% | ||||

| C99 | 99 | 0.05 | 0.5 | 0.5 | 0.5 |

| C98.5 | 98.5 | 0.2 | 0.8 | 0.7 | 0.5 |

| C98 | 98 | 0.3 | 0.8 | 0.8 | 0.5 |

| C90 | 90 | 0.3 | 9 | 10 | 0.5 |

Please feel free to submit your inquiry information to us, We will reply to you as soon as possible.